What makes a stretch wrapping machine essential for manufacturers

What makes a stretch wrapping machine essential for manufacturers

Blog Article

Improve Your Packaging Process With a Reliable stretch wrapping machine for Optimum Performance

In the complicated world of logistics, an effective packaging process is a critical element that can significantly influence a company's profits. The unification of a reputable stretch wrapping machine not only maximizes performance yet also makes certain the integrity of products during transit. This piece of equipment can be the secret to opening enhanced productivity, waste decrease, and substantial expense savings. Intriguing, isn't it? Let's discover even more.

Recognizing the Duty of a stretch wrapping machine in Packaging

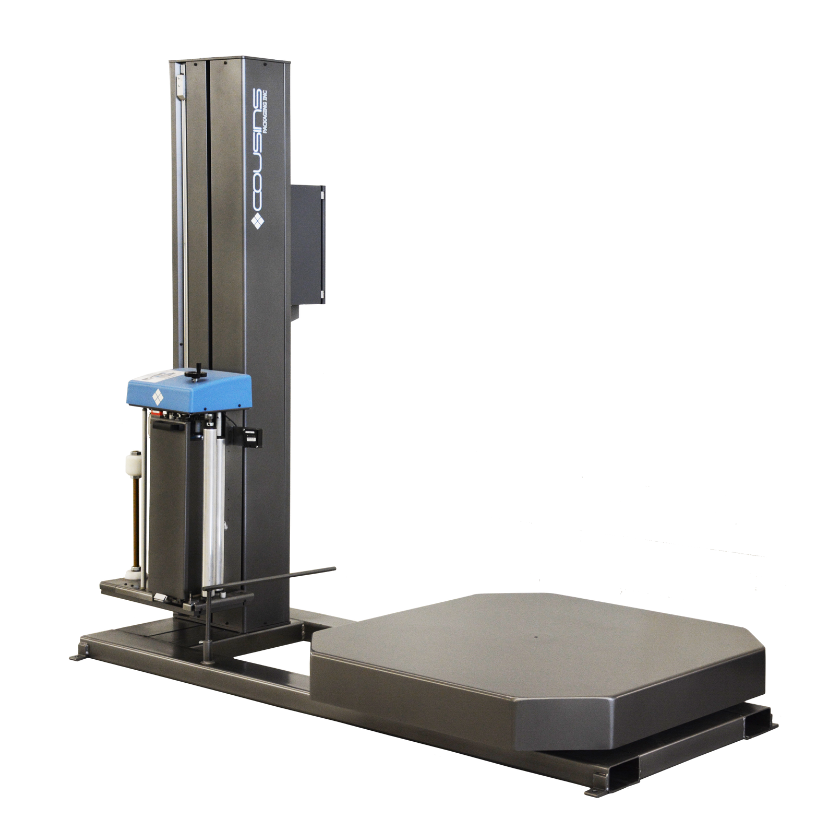

Guaranteeing item security throughout transit, a stretch wrapping machine stands as a crucial possession in the packaging industry. Its key role rotates around enveloping things in a safety layer of film, consequently protecting product stability and minimizing damages risks throughout transport.

The maker's procedure is elaborate yet effective. Product are positioned on a turning base while the film is untangled from a fixed roll. As the turntable spins, the film is used uniformly over the objects, ensuring complete protection.

This machine's relevance expands beyond mere covering. stretch wrapping machine. It enhances the stacking security of products, minimizing the possibility of accidents. Additionally, it safeguards things from dirt, wetness, and various other ecological variables, preserving their quality until they get to the consumer

Fundamentally, a stretch wrapping machine is an important device for organizations seeking to enhance their product packaging procedure, secure their products, and improve their logistics operations. Its function is integral to the reliable and efficient functioning of the contemporary product packaging industry.

Trick Features to Consider When Choosing a stretch wrapping machine

When choosing a stretch wrapping machine for product packaging purposes, numerous crucial functions call for consideration. These include examining the maker's performance, comprehending its lots capability, and examining its resilience and upkeep requirements. An informed decision depend upon a detailed analysis of these aspects.

Although effectiveness could not be the first point you consider when considering stretch wrapping devices, it is an important variable that can substantially affect your packaging procedure. An efficient equipment can substantially lower waste, lower prices, and improve performance. When evaluating performance, consider the device's rate. A faster device can cover much more plans in less time, increasing your operation's outcome. Also, look for programmable setups, which can personalize the wrapping process to match different items, decreasing unnecessary usage of products. In addition, an efficient machine should call for marginal upkeep, guaranteeing continual operation without constant interruptions. The machine's energy consumption is another critical aspect, as a device that utilizes much less power can reduce running costs. Bear in mind, an effective device guarantees ideal efficiency.

The Influence of a Trustworthy stretch wrapping machine on Performance Degrees

Investing in a reliable stretch wrapping machine can significantly enhance performance levels in a product packaging operation. These makers automate the covering procedure, allowing for efficient and constant performance that outpaces hands-on wrapping approaches.

A trusted device reduces downtime caused by mechanical failures or upkeep demands. High-grade stretch wrapping machines likewise have flexible setups for various product types.

In addition, these equipments need less human intervention, maximizing staff members to concentrate on various other important jobs. This reference optimization of human sources can lead to a rise in general operational productivity.

Essentially, a dependable stretch wrapping machine is a beneficial financial investment that can enhance performance levels in a packaging procedure, giving significant benefits in resource, performance, and flexibility utilisation.

Ways in Which a stretch wrapping machine Decreases Waste

A stretch wrapping machine's role in waste reduction is considerable and complex (stretch wrapping machine). Not only does it reduce material usage by successfully wrapping items, but it likewise safeguards items from damage throughout handling and transport. This twin advantage cause noteworthy price savings and advertises sustainability in the packaging process

Decreasing Material Usage

Price and Time Cost Savings: The Economic Advantages of a stretch wrapping machine

Furthermore, the device's consistent wrapping technique reduces product damages, decreasing replacement prices and enhancing consumer fulfillment. The use of a stretch wrapping machine likewise results in a more predictable budgeting procedure, as the amount of stretch movie utilized per pallet is constant, unlike manual wrapping which can vary substantially.

Ultimately, the advancing savings in labor, products, and possible product loss make the preliminary financial investment beneficial. In the long term, businesses can accomplish significant financial benefits by integrating a stretch wrapping machine into their product packaging process.

Verdict

Although efficiency might not be the first point you believe of when taking into consideration stretch covering machines, it is an important aspect that can significantly influence your product packaging procedure. The machine's power intake is an additional crucial variable, as a maker that uses less power can reduce running costs. Furthermore, a device sustained by a websites thorough service warranty and superb customer service can ease prospective problems in preserving the equipment's optimum performance.To comprehend the methods in which a stretch wrapping machine decreases waste, one have to initially take into consideration the cutting-edge design of these equipments. In this method, stretch covering equipments not just boost the quality of product packaging but likewise foster an extra environmentally-friendly and efficient process, showing their important role in modern packaging procedures.

Report this page